Pottery tradition of Ljutomer

Pottery is one of the oldest crafts in Slovenia, as evidenced by numerous archaeological finds from

various historical periods. The oldest written evidence of pottery is said to have been preserved for

the Zadrečka Dolina area in 1340. Pottery developed in areas that are rich in clay. Ljubno na

Gorenjské, Komenda, Ribniška dolina, Šentjernejsko polje, Dravsko polje and Pomurje are famous as

the oldest pottery centers in Slovenia. The individual centers differed from each other in the type of

clay, technology, shapes and decoration.

Potters from northeastern Slovenia were known for their quality bowls, baking trays, baking trays for

meat and strong dishes, sour milk pots, cheese colanders, washing and cooking pots, large jugs for

storing vinegar, jugs for water and wine, and baking trays for cakes. In addition to their home

workshops, the main sales premises of potters were village, Trieste or city fairs. The potters of

Ljutomer broke away from the main guild in Graz on December 7, 1602. Archduke Ferdinand II

granted them a patent with rules. May 1603. It is known that in later centuries the Ljutomer guild

was also confirmed by Ferdinand III. (1645), Leopold I. (1660), Charles VI. (1713) and Maria Theresa

(1746). Potters who were part of the Lutomer guild had to adhere to a rulebook consisting of 58

points.

Among other things, they had to regularly participate in processions on the Feast of the Holy

Redeemer, Holy Mass on the feast day of St. Florian and on the day of St. Nicholas. On church

holidays, they were not allowed to burn dishes and fire in the oven. The master was able to open his

workshop when he submitted a certificate of passing the exam and a baptismal certificate. Before

being accepted into the guild, he had to successfully make five products: two large bottle-shaped

pots with lids, a pitcher, one button, and a "kahla" (oven) placed in a furnace. In addition, he had to

acquire the status of a market man, present 60 pieces of kitchenware to the mayor and donate four

wine glasses to the poor people in the hospital. The master could teach only one student or

apprentice at a time in the workshop. All assistants who wanted to become masters had to gain

experience in other Slovenian provinces for two years.

In 1751, the Ljutomer guild had seven masters. Four came from Ljutomer, and one each from Križevci

near Ljutomer, Cezanjevci and Radoslavci. A good hundred years later, in 1859, the number of

masters increased to twelve. Two assistants and three students were also registered that year. In

1946, eleven potters were registered in the Ljutomer District Chamber of Crafts. In 1959, seven

pottery factories were listed, namely in Ljutomer, Noršinci, Šalinci, Radoslavci, Sitarovaci,

Ključarovaci and on Stara Cesta. With the exception of the Žumans, who had an assistant and an

apprentice, the masters did the work themselves. At the end of the 20th century, the Žuman family

was the only pottery family that continued to preserve the rich tradition of pottery in the Ljutomer

area.

Today, a good number of potters in Slovenia continue the rich pottery heritage, technologically and

functionally adapting it to modern times. The activity of modern potters is still mostly connected with

old pottery centers and clay deposits. The holders of this activity continue the decades-long tradition

of family heritage.

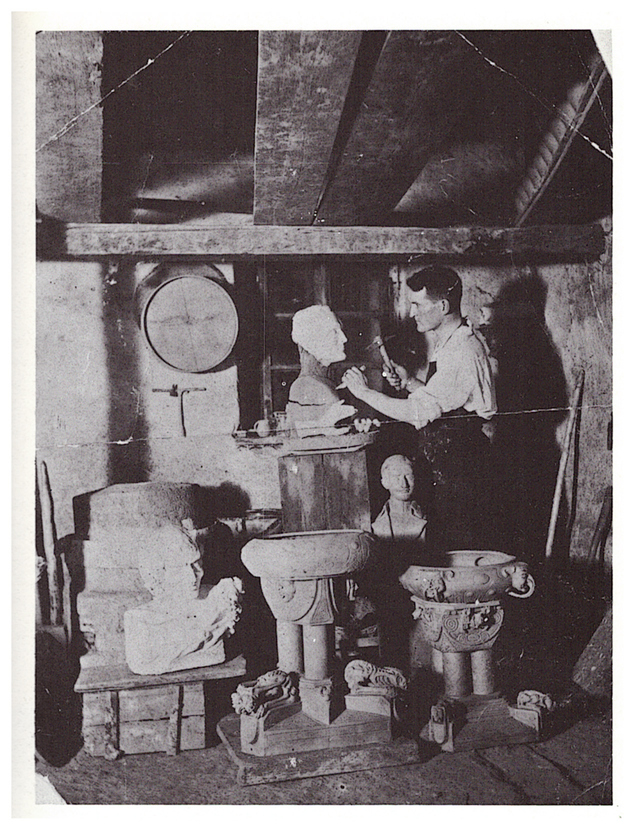

In the Ljutomer region, the pottery tradition is preserved by the Žuman family, which can boast of

almost 150 years of activity. The Žuman family has been passing down the pottery craft from

generation to generation since 1874. Saša Žuman is already the fifth generation of potters in the

family. Pottery skills were handed down to him by his father Branko Žuman and grandfather Karel

Žuman, who opened his workshop in Ljutomer in the 1970s. Karel was the first potter in Slovenia to

set up a shop and gallery of his best products next to his workshop. The processes of making pottery

products have not changed significantly since the 19th century, when the Žuman family started

working with pottery, until today. The family has been digging clay in Lukavace, near the old brick

factory, for several decades. Every year, they accumulate about two tractor-trailers worth of clay,

which they store over the winter at home in a landfill. Frozen clay is ground in the spring in a special

mill with two rollers that flatten the clay into a one millimeter thin layer. The clay is then kneaded

and mixed, and depending on the product, a certain amount of water is added. Kneaded clay is

formed into lumps of different sizes, depending on the individual product. They begin to form a

precisely measured amount of clay on an electric potter's spindle. The molded products must then

dry well. Drying can take from one week to one month, depending on the thickness and size of the

product.

This is followed by the firing process. The first brandy or biscuit firing takes place at 800-900 ˚C and

lasts 12 hours. About 2 m3 of firewood is used for this. The second, glaze firing takes place at 1000 ˚C

and lasts 15 hours. They use 3 m3 of firewood for this kind of brandy. The most suitable "soft" wood

for firing pottery is spruce, alder or birch. After the second firing, they leave the products in the kiln

for another two days to cool down well. Then they are coated with lead-free transparent glazes that

contain pigment additives. The Žuman family manufactures various baking pans, jugs, handles, butter

jars and "dükles" for pickling milk.